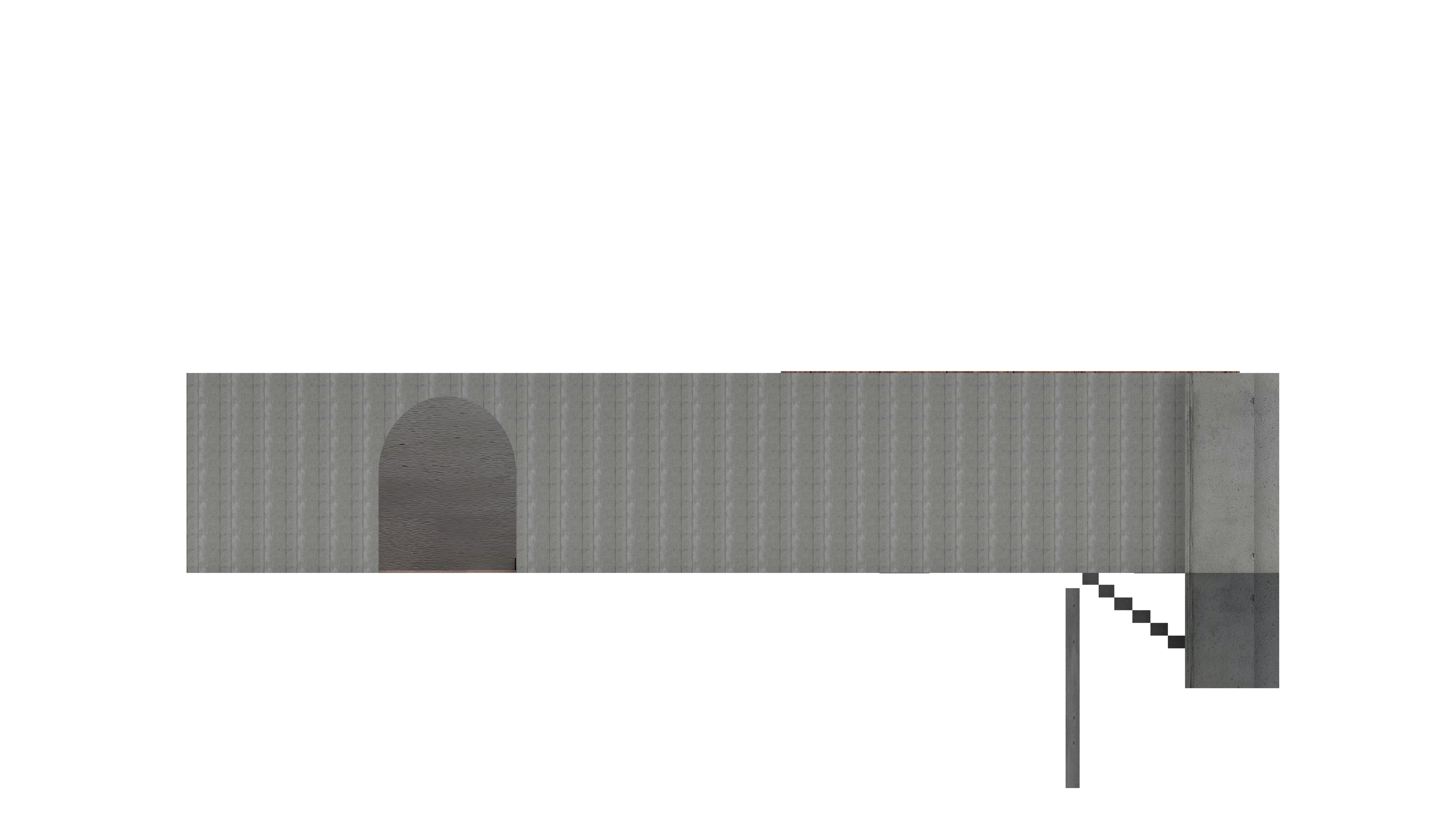

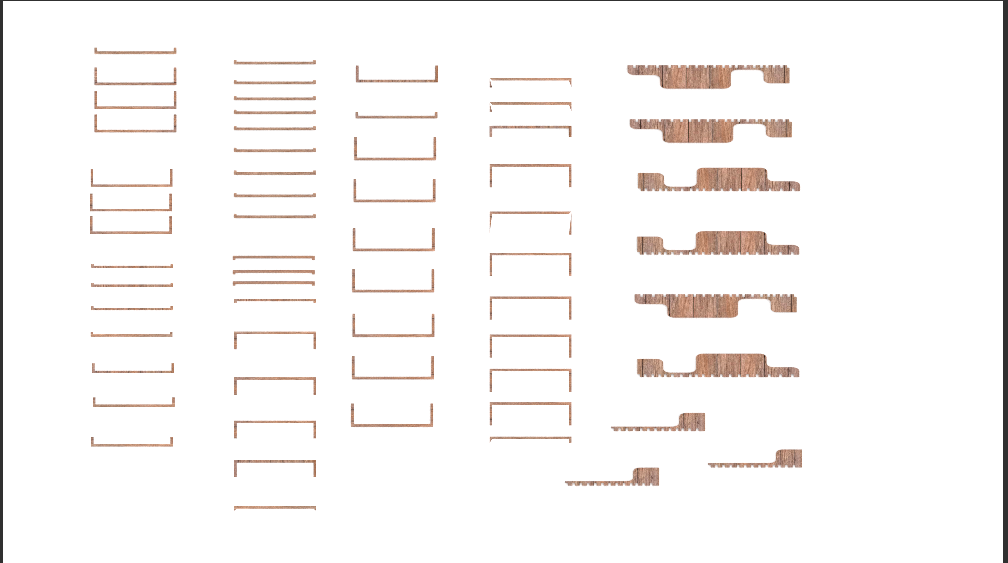

A couple of days ago I went to laser cut my model only to find that it was in the completely wrong scale. Instead of being 1:20 it was much smaller. Confused as to how this had happened I re opened my rhino to investigate. When exporting from Rhino to illustrator I didn’t make sure to conserve the scale meaning that it was distorted, After changing it back to normal I was back in action and headed back to get it cut.

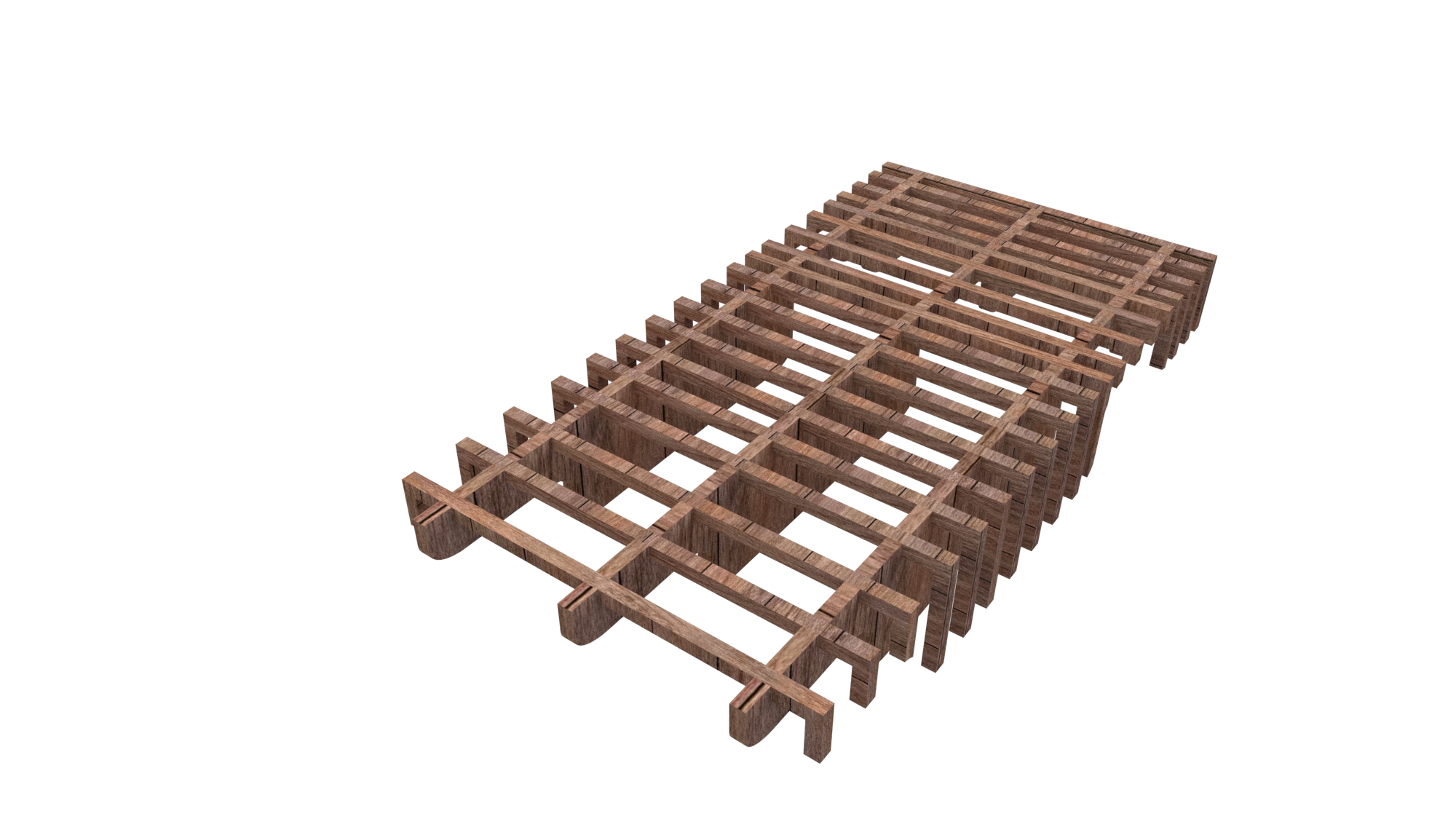

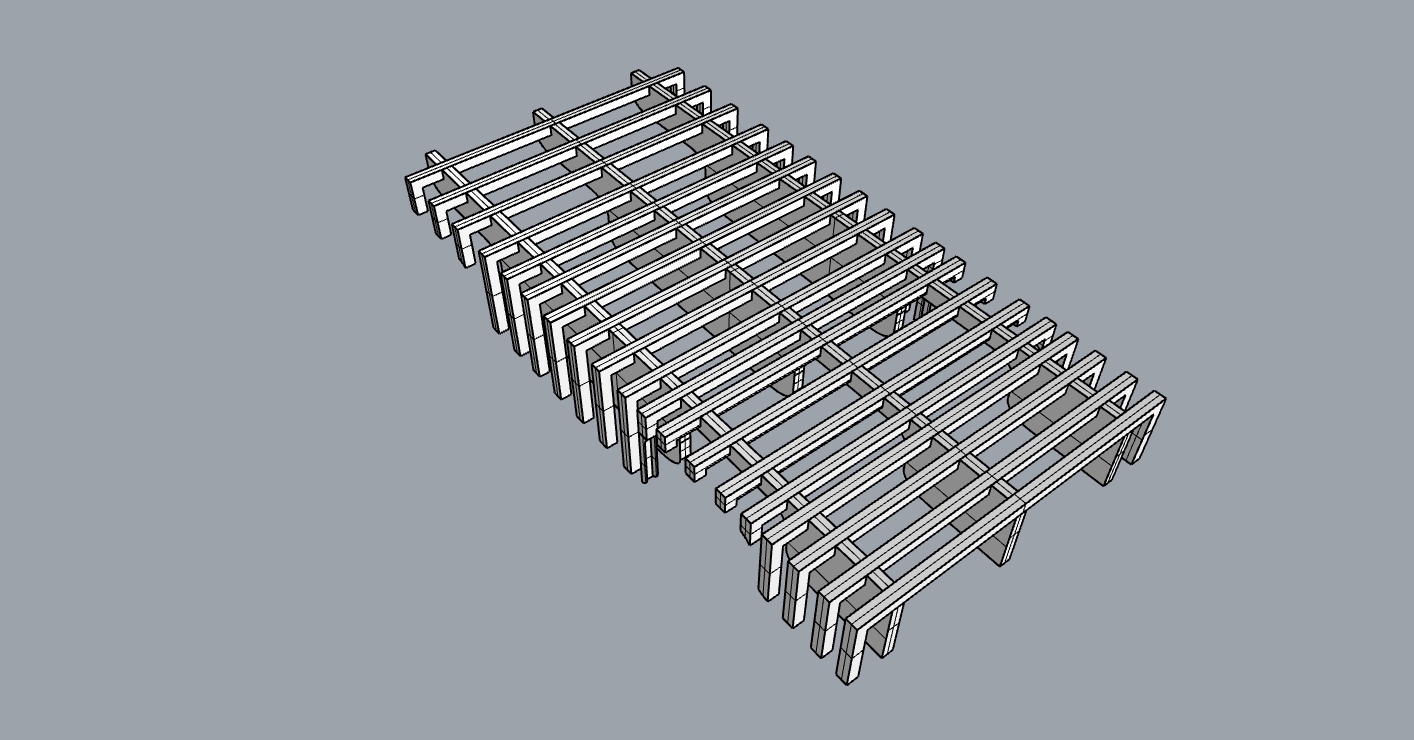

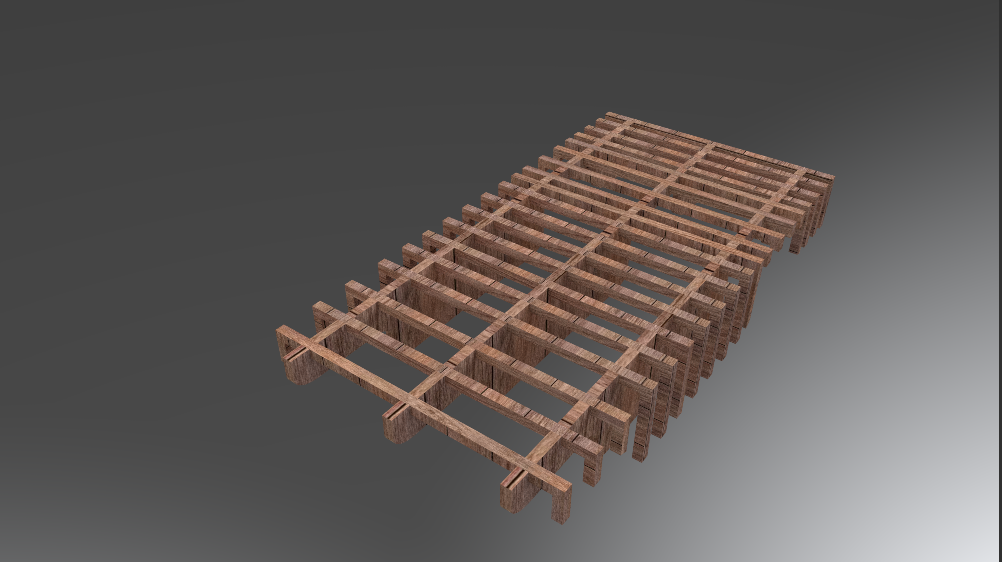

My model has 3 main components to it. There is curved forms the waffle frame sections and the flexible curved kerf panels. As my sleeping platform design takes up majority of the gallery space this resulted in my 1:20 model being rather large and as a result of this I have to use several sheets of MDF.

I decided to go with 6mm MDF as it seemed best suited to a model of such size. If I had used 3mm I feel as if it would have looked out of proportion in a way.

MDF isn’t the prettiest of materials, it has no grain meaning that it looks flat and has no texture to it. In an attempt to try and resolve this problem I decided to try varnish the wood. I went off to bunnings and told them what I was planing to do and they pointed me in the right direction.

They recommend that I get something simple and easy to use a stain and polyurethane all in one type of thing. I took their advice and bright was u can see on the left.

Now traditionally with a stain or varnish you apply it normally with a brush or cloth let it rest for around 5mins then rub off the excess and let the grain of the wood do all the work, however like I mentioned before MDF if plain so in an attempt to try and create my own (fake) grain I applied it on thick and let it dry all streaky. This was a bit of beginners luck but it actually turned out all right.

It looks as if each individual section has been cut out from a plank of wood. I am very pleased with the final outcome.